Plastic Pail Shipping Boxes

Smart Pail®

Product Categories

Equipment Options

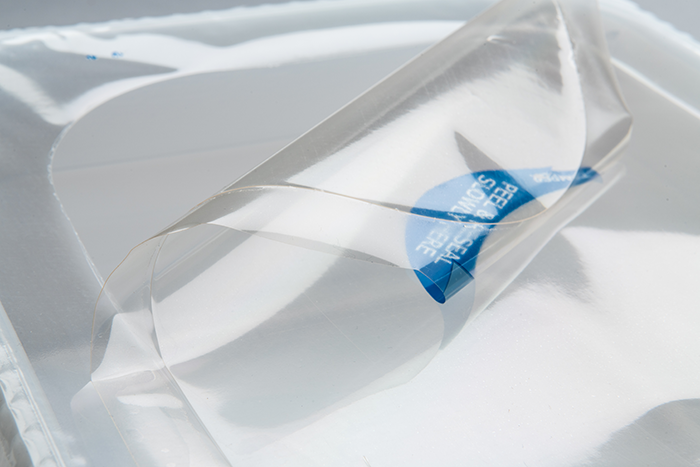

Lidding for Smart Pail®

Smart Pail® Inserts

Disrupting and Transforming

Traditional Packaging

At CDF, we are proud to be a frontrunner in creating disruptive and innovative packaging technology and solutions. Let our award-winning mindful packaging transform your supply chain.

Sustainable Replacement for Plastic Pails

The Smart Pail, is a semi-rigid, vacuum-formed alternative for plastic pail shipping boxes with a peel-reseal lidding film housed within a perfectly formed Smart case. Designed for protective industrial and e-commerce shipping, offering great supply chain versatility.

Designed as a more sustainable plastic pail replacement solution for the transportation of semi-viscous, solids and liquids, Smart Pail offers superior branding potential, lower total cost, optimized storage and inventory, improved ergonomics, and greater customer satisfaction.

See How It Works

Demonstrated Sustainability

Smart Pail®

The Smart Pail® was developed to offer a more sustainable and cost-effective system for transporting semi-viscous solids and liquids traditionally shipped in plastic pails. The Smart Pail is a semi-rigid, flexible vacuum-formed plastic liner with a unique laminated peel-reseal lidding film structure offering tamper evidence, easy open-close, excellent oxygen barrier, and efficient disposal.

- Various lid film options including peel/reseal, peel and dispose of the lid, barrier, and recyclable.

- Printed resealable film lid provides an excellent oxygen barrier that ensures product purity, making it ideal for food applications.

- Unique tamper-evident system integrated into the film lidding.

Shifting Your Operation to Smart Pail

Lower your operational, storage, handling, and transportation supply chain costs with Smart Pail:

- The multi-faced container that holds the Smart Pail allows for greater opportunities for brand exposure and visibility

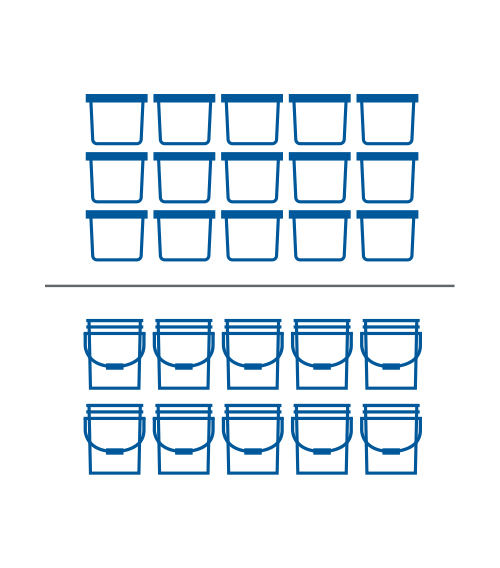

- The Smart Pail uses 80% less plastic than comparable plastic pails due to the unique design and stacking strength

- Smart Pail provides 33% more product per outbound shipment

- The Smart Pail is collapsible and recyclable for easy disposal

Find Your Packaging Solution Today!

If you have a specialized need that requires a Mindful Solution, contact us to speak with one of our packaging experts.

Have a Question About this Product?

Our expert engineers can guide any client within any industry with a mindful solution to meet their packaging and sustainability needs, from innovative research and development to customizable designs.

With over 50 years of experience, our team of engineers collaborates with each customer to design a new packaging solution from liner selection to full systems integration to modifying existing products.